18 January 2025

The content of the present page, (since 2018 I think), is lost, due to technical, (unknown Google's), reasons.

After many years of research and development, I 'll present to you the updated, 2025 results, which bring, nearer than ever, the achievement of an emissions free g60 petrol engine, (hopefully).

BOSCH W8DCO CU

BERU Z1 14-8DU

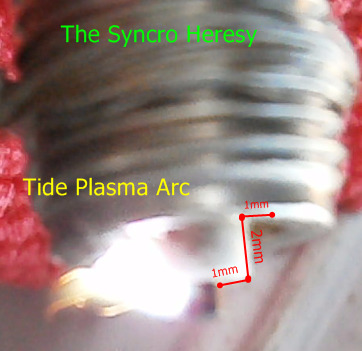

A central copper spark plug, with 2.5 m.m. central electrode, @ 3 m.m. firing point, @ 4 m.m. gigantic, industry dream, gap, strapless, working as a semi-surface discharge spark plug, resistorless, plasma arc supporting and supported by plasma.

More are coming!

23 January 2025

Perfect fuel discovered for the first time in history: It’s not electricity, not hydrogen

by Edwin O.

January 21, 2025

in Mobility

Credits: American Nuclear Society

Recent inventions have shown immense promise, and scientists have made a claim that could change the entire engineering area. They have introduced a fuel with the highest potential compared to any other fuel; it clearly surpasses electricity and hydrogen. It can be referred to as the ignition, and the promised effects that it can have on combustion engines are truly remarkable. With this new technology, an effective implementation of a different approach can be expected. This article discusses the science behind this discovery, its possible consequences, and its workings.

Plasma ignition explained: how it replaces outdated spark plugs

Instead of relying on screw-in diesel glass tubes, plasma ignition runs off controlled electronic bursts that are much more powerful and help ignite fuel faster. In contrast to a typical spark plug that creates a momentary electric spark, which is limited in nature and capacity, plasma ignition ensures complete fuel combustion in a more rapid and effective manner. As a result of this advancement, the pollutants released by the engine have been significantly lowered, and the fuel usage economy has improved, too.

Lastly, one strong point that can be made about plasma is its wide array of fuels that it can use, ranging from different biofuels to more promising options, making it a potential candidate for different sectors. Furthermore, the technology guarantees the ability to tackle thermal efficiency, a challenge many have faced when finding alternative energy sources.

The carbon dioxide and nitrogen oxides formed from burning fossil fuels are greenhouse gases that most transport and combustion engines use. Transportation is responsible for one-third of greenhouse gas emissions in the United States alone. A barrage of measures and mechanisms has been designed to ameliorate this ecological concern; however, internal combustion engines still contribute strongly to pollution.

Why plasma ignition may change the game for the environmental sustainability targets?

By enhancing the combustion process and increasing the engine’s efficiency, plasma ignition technology reduces the emissions and fuel consumption of the vehicle. It does not promise the elimination of the emissions, but it’s progress nevertheless. This could help extend the life of combustion engines without violating global sustainability targets.

Though plasma ignition can be revolutionary, its application has some challenges that must be addressed. The ability of plasma technology is not as high as that of a few emerging technologies that have been developed or are in development. For example, solar-powered additions do not provide much more car range and might only interest campers and people who commute in sunnier climates.

In addition to that, the cost of adoption is another hurdle. It’s not hard to guess that plasma ignition systems are not cheap. At the moment, they cost around $10,000. This brings possibilities of mainstream use under question. Even if the tech is appealing, it needs to have considerable benefits over cost and be better than other systems to be used more widely.

The future of clean energy is sparked by a discussion on plasma ignition; why is that?

It should not be implemented, and the reasons are valid. However, the promise of plasma ignition technology is grand and is building up toward energy innovation. Plasma as an ignition method is a clear move away from fossil fuels and their dependence, which society as a whole is quickly growing tired of. And even other alternatives need to be addressed to cover the clean energy requirement. Rather than usurping existing approaches such as hydrogen and battery power, plasma ignition is expected to be an added technology to existing technologies.

Its capacity to curb greenhouse emission gases will be ascertained by its ability to function in the real world. For the time being, this technology is a vital element in ensuring an energy-sustainable future. The identification of plasma ignition as a form of “perfect fuel” technology heralds a significant breakthrough in the search for a clean alternative to energy. While it is apparent that other cleaner fuels technologies cannot be dispensed with, there is still some room for improvement, and new ones, such as fuel additives, are forth coming.

In conclusion, plasma ignition technology is intriguing and holds great promise as a breakthrough. When fused with other clean energy technologies, its enablement for a wide fuel range and its effective and flawless combustion alongside low emission levels all add to its advantages. On the other hand, only time will tell how this clean energy fuel technology will work when commercially produced.

No comments!

Factoid #4:

AI says:

"Spark Plug Voltage Requirements

Typically, the voltage required to jump across a spark plug gap can be estimated. For a 4 mm gap, the ignition voltage can be significantly higher than for smaller gaps. Here’s a general guideline for spark plug gap voltages:

"

* But we know that for a g60 Bosch, (or Beru), distributor cap, the ~ 30 KV is the limit!

How is it possible for a 4mm gap to work, (especially for a forced induction engine?)?

The answer is the "surface discharge" phenomenon which reduces the resistance, (at about the half), that the voltage has to overcome.

For the specific semi-surface discharge spark plugs, the gap is divided to 3mm surface and to 1mm air discharge, which is equal ~ to 2.5 mm gap or, (according to the above table), 20-25 kv, within the limits, (and with an enough margin for the extra demands, as it is obvious from the perfect operation), of the distributor cap, (with a modified copper central tab).

AI says:

"Spark Plug Voltage Requirements

Typically, the voltage required to jump across a spark plug gap can be estimated. For a 4 mm gap, the ignition voltage can be significantly higher than for smaller gaps. Here’s a general guideline for spark plug gap voltages:

| Gap Size (mm) | Approx. Operating Voltage (kV) |

|---|---|

| 1.0 | 6-10 |

| 1.5 | 12-15 |

| 2.0 | 15-20 |

| 2.5 | 20-25 |

| 3.0 | 25-30 |

| 3.5 | 30-35 |

| 4.0 | 35-40 |

* But we know that for a g60 Bosch, (or Beru), distributor cap, the ~ 30 KV is the limit!

How is it possible for a 4mm gap to work, (especially for a forced induction engine?)?

The answer is the "surface discharge" phenomenon which reduces the resistance, (at about the half), that the voltage has to overcome.

For the specific semi-surface discharge spark plugs, the gap is divided to 3mm surface and to 1mm air discharge, which is equal ~ to 2.5 mm gap or, (according to the above table), 20-25 kv, within the limits, (and with an enough margin for the extra demands, as it is obvious from the perfect operation), of the distributor cap, (with a modified copper central tab).

24 January 2025

Ai questions and answers:

Q#1:

Which is the widest spark plug gap, ever achieved, to work for a car engine?

A:

As of my last knowledge update in October 2023, the typical spark plug gap for most automotive applications ranges from 0.028 to 0.060 inches (0.7 to 1.5 mm), depending on the engine design and performance specifications. However, there are specialized applications, particularly in high-performance or racing engines, where wider gaps may be utilized to increase spark energy and improve combustion efficiency.

In some experimental or highly specialized racing applications, spark plug gaps may be set as wide as 0.080 inches (2.0 mm) or more. However, these setups often require specific ignition systems capable of generating enough voltage to jump the wider gap reliably.

It's important to note that while wider gaps can enhance performance, they also come with challenges like increased likelihood of misfire and the need for a stronger ignition system. Additionally, what works best can vary greatly depending on the specific engine and tuning conditions.

If there have been any new records or developments after October 2023 regarding spark plug gaps in automotive applications, please consult more recent sources for updated information.

Q#2:

For experimental or highly specialized racing applications, which is the widest, ever, spark plug gap?

A:

While there isn't a definitive record for the absolute widest spark plug gap ever used in experimental or specialized racing applications, reports and anecdotal evidence suggest that gaps of around 0.100 inches (2.54 mm) or slightly wider have been used in some extreme high-performance contexts. These applications often involve modified engines with high-energy ignition systems designed to handle the increased voltage required to create a spark across such a wide gap reliably.

It's essential to note that while wider spark plug gaps can improve ignition and combustion efficiency in specific situations, they also pose challenges, such as increased chances of misfires and the necessity of advanced ignition technology. The practicality of using such wide gaps depends heavily on the overall engine configuration, the type of fuel used, and tuning considerations.

If you're interested in the latest developments or specific records, it would be worthwhile to explore resources from racing organizations, automotive engineering publications, or technical forums dedicated to performance tuning.

Q#1:

Which is the widest spark plug gap, ever achieved, to work for a car engine?

A:

As of my last knowledge update in October 2023, the typical spark plug gap for most automotive applications ranges from 0.028 to 0.060 inches (0.7 to 1.5 mm), depending on the engine design and performance specifications. However, there are specialized applications, particularly in high-performance or racing engines, where wider gaps may be utilized to increase spark energy and improve combustion efficiency.

In some experimental or highly specialized racing applications, spark plug gaps may be set as wide as 0.080 inches (2.0 mm) or more. However, these setups often require specific ignition systems capable of generating enough voltage to jump the wider gap reliably.

It's important to note that while wider gaps can enhance performance, they also come with challenges like increased likelihood of misfire and the need for a stronger ignition system. Additionally, what works best can vary greatly depending on the specific engine and tuning conditions.

If there have been any new records or developments after October 2023 regarding spark plug gaps in automotive applications, please consult more recent sources for updated information.

Q#2:

For experimental or highly specialized racing applications, which is the widest, ever, spark plug gap?

A:

While there isn't a definitive record for the absolute widest spark plug gap ever used in experimental or specialized racing applications, reports and anecdotal evidence suggest that gaps of around 0.100 inches (2.54 mm) or slightly wider have been used in some extreme high-performance contexts. These applications often involve modified engines with high-energy ignition systems designed to handle the increased voltage required to create a spark across such a wide gap reliably.

It's essential to note that while wider spark plug gaps can improve ignition and combustion efficiency in specific situations, they also pose challenges, such as increased chances of misfires and the necessity of advanced ignition technology. The practicality of using such wide gaps depends heavily on the overall engine configuration, the type of fuel used, and tuning considerations.

If you're interested in the latest developments or specific records, it would be worthwhile to explore resources from racing organizations, automotive engineering publications, or technical forums dedicated to performance tuning.

%20logo.bmp)

No comments:

Post a Comment