The water into the battery pack and other horror stories:

"

[edit]

"

Explosion Upon Impact

So, for all these billions of electric cars to come, globally, we need more Nuclear Power?

The Fukushima Daiichi nuclear disaster.

Forbes

Surprise:

"Nuclear Power Maximizes Environmental Benefits Of Electric Vehicles

"UK could need 20 more nuclear power stations if electric cars take over our roads and cause ‘massive strain’ on power network"

11/April/2018

The next Tesla "electric" car will have a Plasma petrol engine!

(Yes, I know, you cannot believe it!)

Article excerpt:

Comment:

The listing for cobalt includes different types of cobalt compounds that release ions into the body.

It does not include vitamin B-12, because cobalt in this essential nutrient is bound to protein and does not release cobalt ions.

Cobalt is a naturally occurring element used to make metal alloys and other metal compounds, such as military and industrial equipment, and rechargeable batteries.

The highest exposure occurs in the workplace and from failed surgical implants.

The listing for this metal and its compounds is based largely on studies in experimental animals.”

(link)

An youtube video is deleted here. A new version is coming asap.

Article excerpt.

"Gaining traction, losing tread Pollution from tire wear now 1,850 times worse than exhaust emissions

By some distance, the research Emissions Analytics published in early 2020 claiming that tire particulate wear emissions were 1,000 times worse than exhaust emissions generated the most feedback of any subject we have tackled so far – feedback that was a mixture of surprise and scepticism.

Of particular attention was whether such a rate of wear would mean that any tire could be spent within just a few thousand miles with legal driving, however aggressive. Particularly vocal were the battery electric vehicle (BEV) community, sensitive to any suggestion that the added weight of these vehicles might lead to tire wear emissions that might confound the ‘zero emissions’ tag. Such was the reaction, the story was translated into over 40 languages worldwide.

Since

that study, which was transparently designed to quantify the worst-case

tire emissions under legal driving, Emissions Analytics has been

testing and analysing tire wear emissions in more detail across a wider

range of driving conditions, and has performed a detailed chemical

analysis of hundreds of new tires. Furthermore, we have worked with the

National Physical Laboratory in the UK objectively to quantify the

uncertainties in our measurements of chemical composition.

The

headline conclusion we draw now is that, comparing real-world tailpipe

particulate mass emissions to tire wear emissions, both in ‘normal’

driving, the latter is actually around 1,850 times greater than the

former. Yes, in normal driving the ratio is almost double the previous

figure for aggressive driving.

Quoting such ratios, however,

needs careful interpretation. The fundamental trends that drive this

ratio are: tailpipe particulate emissions are much lower on new cars,

and tire wear emissions increase with vehicle mass and aggressiveness of

driving style. Tailpipe emissions are falling over time, as exhaust

filters become more efficient and with the prospect of extending the

measurement of particulates under the potential future Euro 7

regulation, while tire wear emissions are rising as vehicles become

heavier and added power and torque is placed at the driver’s disposal.

On current trends, the ratio may well continue to increase.

To

measure tire wear mass emissions, Emissions Analytics uses

high-precision scales to weigh all four wheels – tires and rims

together, without detaching – over at least 1,000 miles on real roads.

This is coupled with a proprietary sampling system that collects

particles at a fixed point immediately behind each tire, which are, via a

sample line, drawn into a real-time detector measuring the size of

distribution of particles by mass and number. Typically, this measures

particles from 10 microns down to 6 nanometres. This combination allows

the real-time signal to be calibrated to the mass loss, and, by using

the size distribution, the proportion of the particles likely to be

suspended in the air can be estimated. All tire emissions figures

quoted here are for the whole vehicle, combining wear from the four

tires.

Tailpipe particles are measured, in similar real-world

conditions, using a diffusion charger analyser for dynamic mass

concentration and a condensing particle counter for number

concentration, both coupled with a standard Portable Emissions

Measurement System (PEMS) to measure total exhaust flow. As a result,

distance-specific mass and number emissions can be derived, which can

then be compared to equivalent tire metrics. A summary of the results

is shown in the table and chart below.

The comparison is best illustrated by way of a bar chart with a logarithmic vertical scale, as shown below.

The

aggressive legal driving is the result from 2020, which was derived

from a Volkswagen Golf driven at legal road speeds on a track, with fast

cornering and maximum permitted payload in the vehicle. The normal

driving results were averaged across 14 different brands of tire tested

on a Mercedes C-Class driven with average dynamics on the road, with

just the driver and no payload in the vehicle. All of these tires were

tested from new. A smaller number of tires were then tested over their

full lifetime in order to estimate the degree to which wear rates

declined over time.

The tailpipe real-world emissions were

measured across four gasoline mid-sized sports utility vehicles from

2019 and 2020 model years, driven on a mix of urban and motorway routes.

The payload was the driver and test equipment only. For these

vehicles, the relevant regulated limit value in Europe – which is the

same limit in force for current vehicles – was 4.5 mg/km for mass and

6.0 x 1011 #/km for number.

Quite

remarkably, but as testament to the filtration efficiency of the latest

gasoline particulate filters (GPFs), tailpipe mass emissions are now as

low as 0.02 mg/km. Gasoline vehicles were tested as they represent the

majority of new passenger cars sold today. Therefore, the mass wear

from new tires is 16 times greater than the maximum permitted from the

tailpipe, but 3,650 times greater than actual tailpipe emissions.

Taking the full-life average tire emissions, that premium falls to the

1,850 times mentioned earlier. The excess emissions under aggressive

driving should alert us to a risk with BEVs: greater vehicle mass and

torque delivered can lead to rapidly increasing tire particulate

emissions. Half a tonne of battery weight can result in tire emissions

that are almost 400 more times greater than real-world tailpipe

emissions, everything else being equal. Nevertheless, it is important

to say that a gentle BEV driver, with the benefit of regenerative

braking, can more than cancel out the tire wear emissions from the

additional weight of their vehicle, to achieve lower tire wear than an

internal combustion engine vehicle driven badly.

An

important difference between tire and tailpipe particle emissions is

that most of the former is understood to go straight to soil and water,

whereas most of the latter is suspended in air for a period, and

therefore negatively affects air quality. This is supported by

Emissions Analytics’ results, which suggest around 11% of the mass of

tire emissions is smaller than 2.5 microns in diameter (defining the

common metric for fine particle dust, PM2.5, which can be airborne).

Therefore, the airborne tire emissions are more likely to be around 8

mg/km as shown in the table above – this is still more than 400 times

higher than tailpipe emissions.

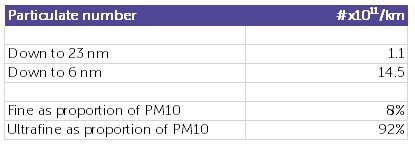

However, considering just tire

mass emissions may underestimate the effect on air quality and the

consequent human health effects. The particulate number can be

estimated, as shown in the second table. When measuring particle

number, the lower size cut-off is important – the smaller the particles

get, the more volatile and harder to measure repeatably they become.

Cutting off at 23 nm avoids these ‘semi-volatiles’, whereas 6 nm is a

much more comprehensive range

This shows that 13.4 x 1011 #/km

are in the size range between 6 nm and 23 nm, which represent 92% of

all particles below the 10 micron upper limit that defines PM10.

Growing scientific evidence suggests that these ultrafine particles

more easily enter the human bloodstream and lungs, and cross into the

brain. The 14.5 x 1011 #/km for the whole size range should also be compared to the maximum number permissible from the tailpipe of 6.0 x 1011 #/km at a 23 nm cut-off, and the actual real-world values from Emissions Analytics’ EQUA test programme of 0.9 x 1011 #/km for gasoline vehicles and 0.1 x 1011 #/km

for diesels. Therefore, tires create more than double the particle

number emissions of the tailpipe, averaged across those two fuel types.

Put another way, tires may release an extra sixty billion particles for

every kilometre driven.

While the body of research on the

health of effects of ultrafine particles is growing, how bad these

effects are is likely to depend on how toxic the particles are.

Light-duty tires are typically made up of synthetic rubber, derived from

crude oil, rather than natural rubber, together with various fillers

and additives. In a recent newsletter, Emissions Analytics set out its

initial findings from chemical analysis of the organic compounds in a range of tires

using two-dimensional gas chromatography and time-of-flight mass

spectrometry. This showed that there were hundreds of different

compounds in each tire, with a significant proportion being aromatics,

some of which are recognised carcinogens.

The next stage is then

to take that chemical profile and study the toxicity of each. Our

research so far shows that the least toxic tires are one-third as toxic

as the worst – this will be the subject of a future newsletter.

Therefore, tires not only vary significantly in wear rates, but also in

chemical composition and toxicity. This potentially points to an

effective way to drive reductions in wear and toxicity through economic

incentives and regulation

Bringing all these elements together, Emissions Analytics will be publishing the chemical composition and toxicity of hundreds of different tires in a subscription database that will be launched in mid-May 2022. The aim is to bring transparency and insight to an area that has historically been under-researched, but which has now been thrown into the spotlight with ever-heavier vehicles and rapidly cleaning tailpipes."

Up to now, pollution from the tires was ignored.

But an electric car is significantly heavier than an conventional car, so its tires pollute more, and, as you can see, this contributes 1850 times more to the pollution than the internal combustion engines!

Do you like to add, in the equation, the pollution from the production of the extra-mega-terra electricity quantities which are needed to feed them?

It seems to be a deception somewhere around here, isn’t it?

10 July 2022

The hybrids are not an exception, as someone may expect:

Article excerpt:

"

EU Clamps Down On Fake PHEV Models

This week, Transport & Environment is reporting that the EU has agreed to assess PHEV emissions based on how much they actually emit on the road. Currently, regulators assume (we all know about the word “assume,” don’t we, boys and girls?) that PHEVs are driven far more in electric mode than is actually the case. Beginning in 2025, the EU will significantly reduce the so-called utility factors, which is the share of electric driving that regulators use for calculating CO2 emissions of PHEVs. From 2027, the utility factors of plug-in hybrids will be fully aligned with how they are driven in the real world. (Translation: manufacturers will be able to continue cheating the system for another 5 years.)

Anna Krajinska, emissions engineer at T&E, said: “For years, the emissions of plug-in hybrids were based on unrealistic driving conditions. The new rules reflect the reality that PHEVs pollute far more than carmakers claim. Governments which still incentivise the purchase of these fake electric vehicles need to stop those harmful subsidies now.”

The latest data shows that, on average, privately owned PHEVs emit three times more carbon dioxide — and therefore use three times more fuel — than recorded officially. For company cars it is even worse. Plug-in hybrids emit five times more than their official ratings. (Note: a plug-in hybrid is just an ordinary car with an internal combustion engine if you don’t plug the damn thing in!) Carmakers have blamed drivers for high emissions, but in reality PHEVs are poorly made with small batteries, weak electric motors, big engines, and usually no ability to fast charge, T&E says."

"GMC Hummer EV Found To Produce More Upstream Emissions Than A Toyota Corolla

The original gas-powered Hummers were always known to guzzle fuel, and a new study has found that the new GMC Hummer EV might unfortunately share its ICE predecessors’ inefficiency.

The study found that in terms of upstream emissions, that is the emissions created from generating the electricity to power an EV, the Hummer produced 341 grams of CO2 per mile. That’s 106 and 112 more grams per mile respectively than the Ford F-150 Lightning and Rivian R1T, two of the truck’s closest competitors. Additionally, the electric Hummer was found to produce more CO2 per mile than even a gas-powered Toyota Corolla, which emits 269 grams per mile, as well as the slightly less fuel-sipping Chevy Malibu, which comes out to 320 grams per mile."